On the occasion of our 90th anniversary, we are organising an open day!

On 12 August, we cordially invite you to come and visit us in our production

On this day you can visit our production hall and get to know our latest innovations that can support you in your production process – whether GLU|ECO®, high-speed aligner or AI-based label presence control.

Discover our powerful technologies for yourself.

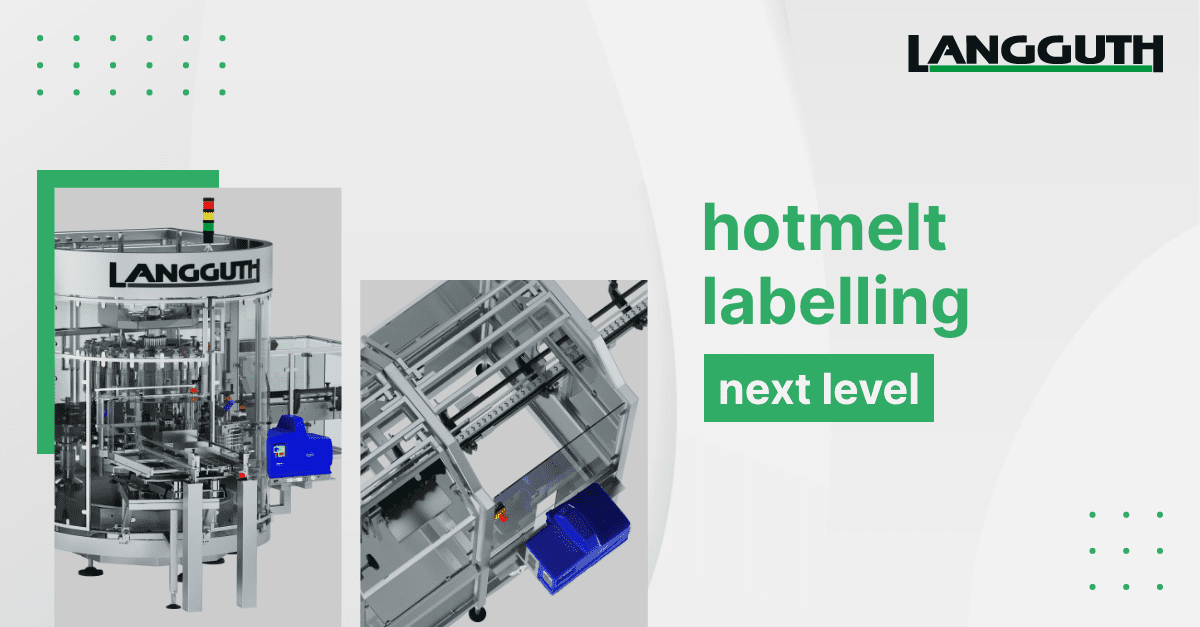

The GLU|ECO® series is the first wet-glue labelling process that enables automated cleaning during the production process. The GLU|ECO® gluing system can be integrated modularly into wet-glue labellers and adjusted to various label sizes by height adjustment.

The development makes wet-glue labelling more economical, especially for frequently changing batches. In addition, a reduction in glue consumption is achieved, which results in a significant cost-saving potential compared to conventional gluing methods. The new glue pump concept also guarantees constant glue quality, ensuring consistently high labelling quality and reproducibility.

Climate neutrality is becoming increasingly important for producers. The GLU|ECO® series contributes to this.

The high-speed aligner was developed for high-precision label application on cylindrical containers. By using a specially developed camera application, distinctive points on the cylindrical containers can be detected. This ensures precise alignment of the containers in flow operation.

The AI-based label presence control achieves a higher level of process reliability in production. With the help of Deep Learning, a photo taken of the container is evaluated and it is decided whether the container has a label. In the process, the system learns continuously.

All this is possible at our open day. The Langguth team is looking forward to your visit!

Then do not hesitate to contact us. Together we will look at your request and advise you gladly.