Our engineers have specifically further developed the well-known spin-spray technology of our hotmelt labelers. By separating the air, the valve is opened with high pressure before the glue dot is sprayed on with comparatively low pressure. This now enables an even more efficient hotmelt labelling process for the hotLAN 310 and moduLAN 800 series.

Whether for labelling food packaging or paint and varnish cans:

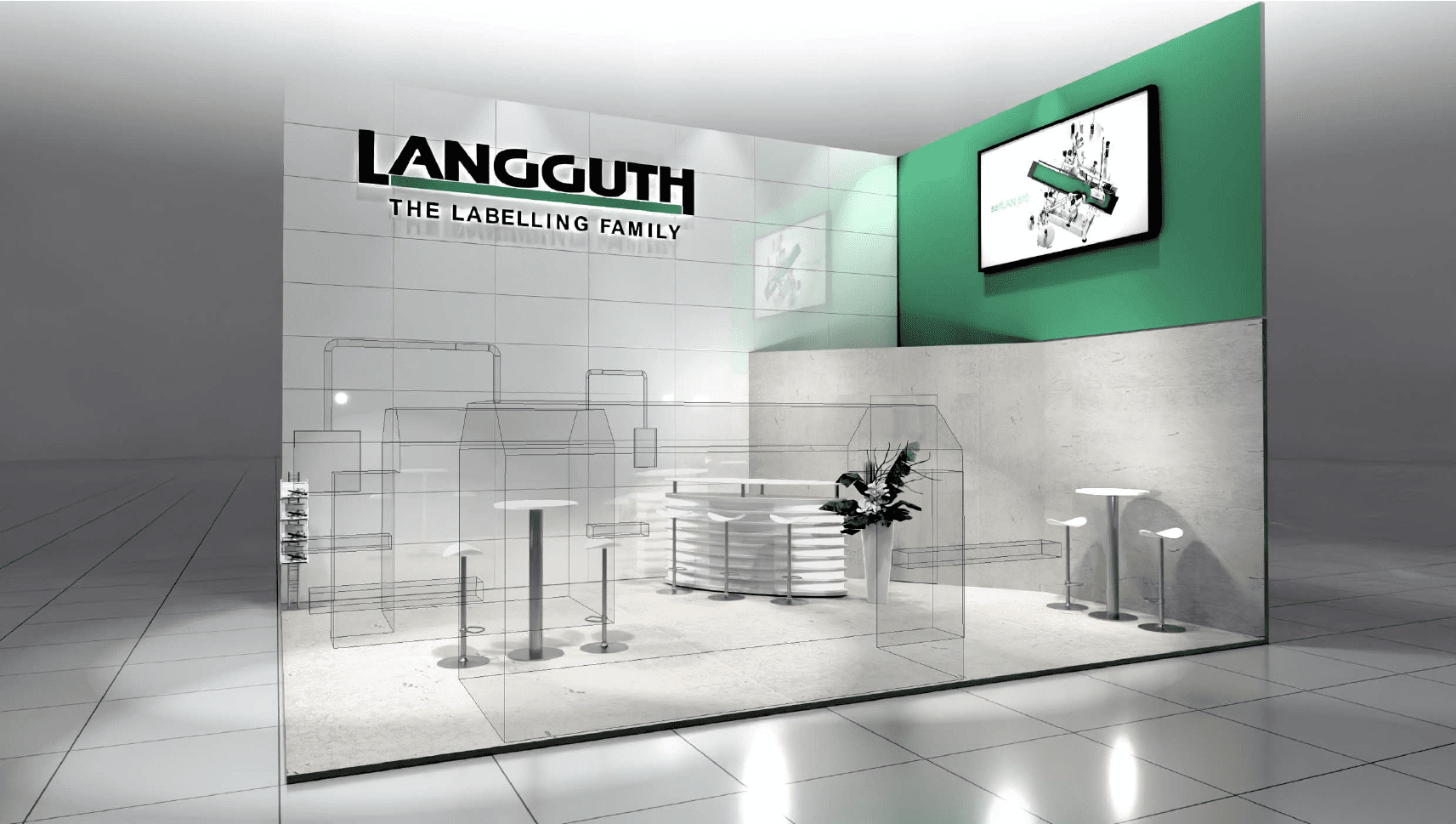

The hotmelt labellers are Langguth’s high-speed machines.

With the improved, glue-saving hotmelt technology, cycle rates of up to 60,000 containers per hour (1,000 CPM) can be achieved. Set-up times between 5 and 10 minutes as well as the non-stop operation of the machine contribute to the high availability and efficiency in production.

You are interested in our labelling machines of the hotLAN 310 or moduLAN 800 series with improved hotmelt concept?

Then please contact us for further information.

The optimized spin-spray process can also be integrated in the previous models of the E40 and E62 series as a retrofit kit!

Then do not hesitate to contact us. Together we will look at your request and advise you gladly.