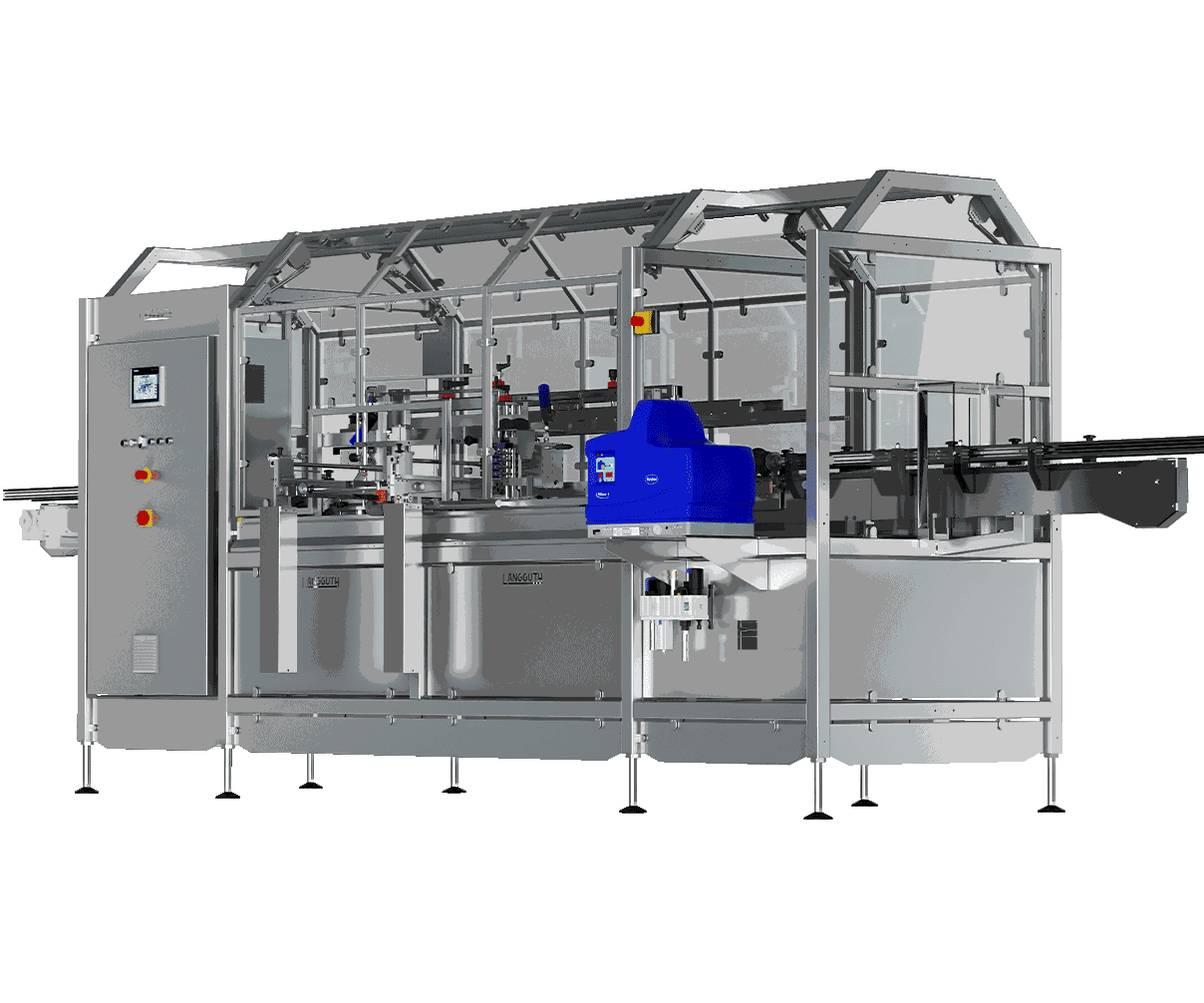

Product labelling with up to 1000 CPM

guarantee efficient labelling

due to spin-spray process

due to short conversion times and simple operation

for high economic efficiency

excludes contamination of the glue

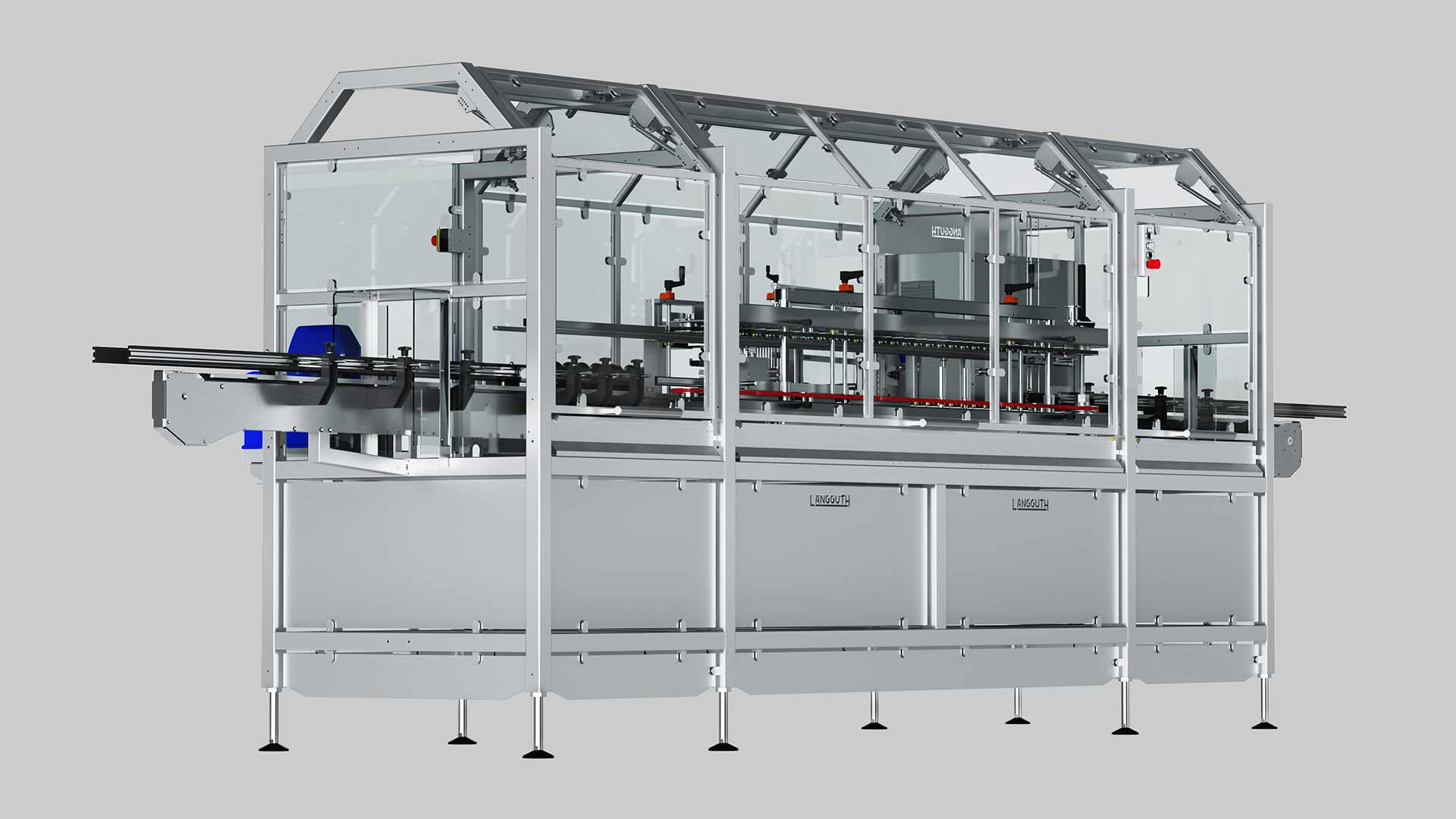

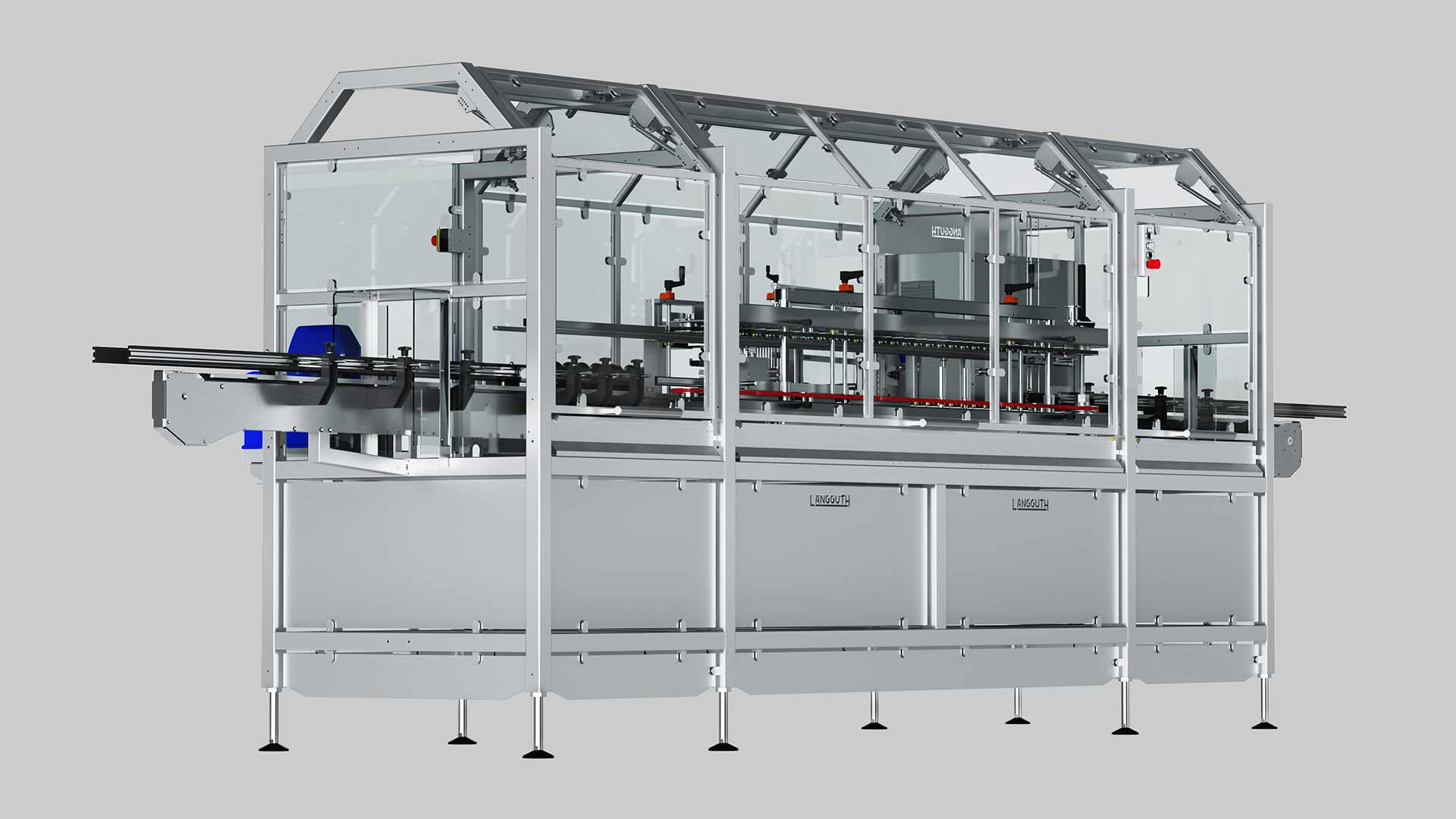

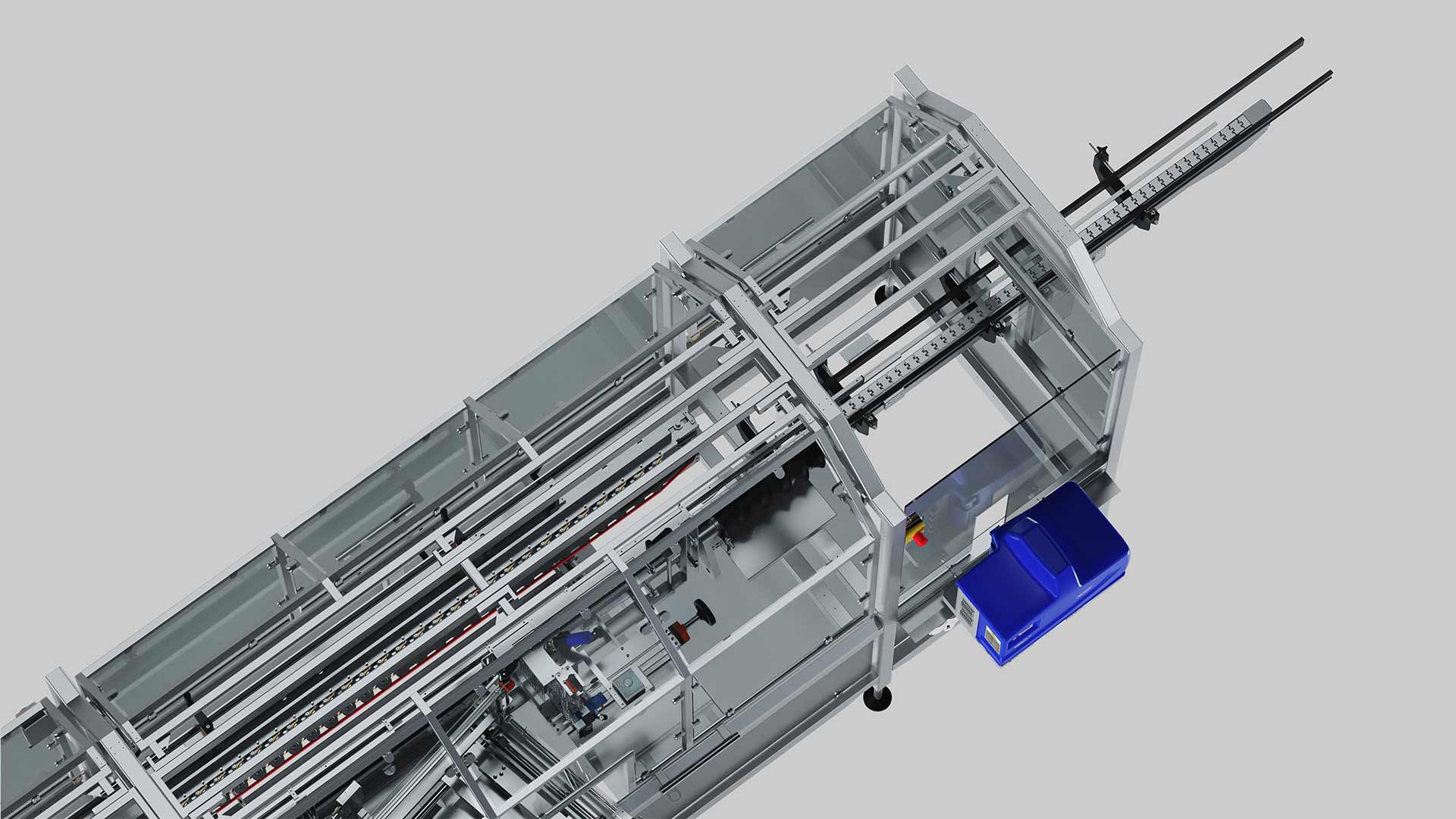

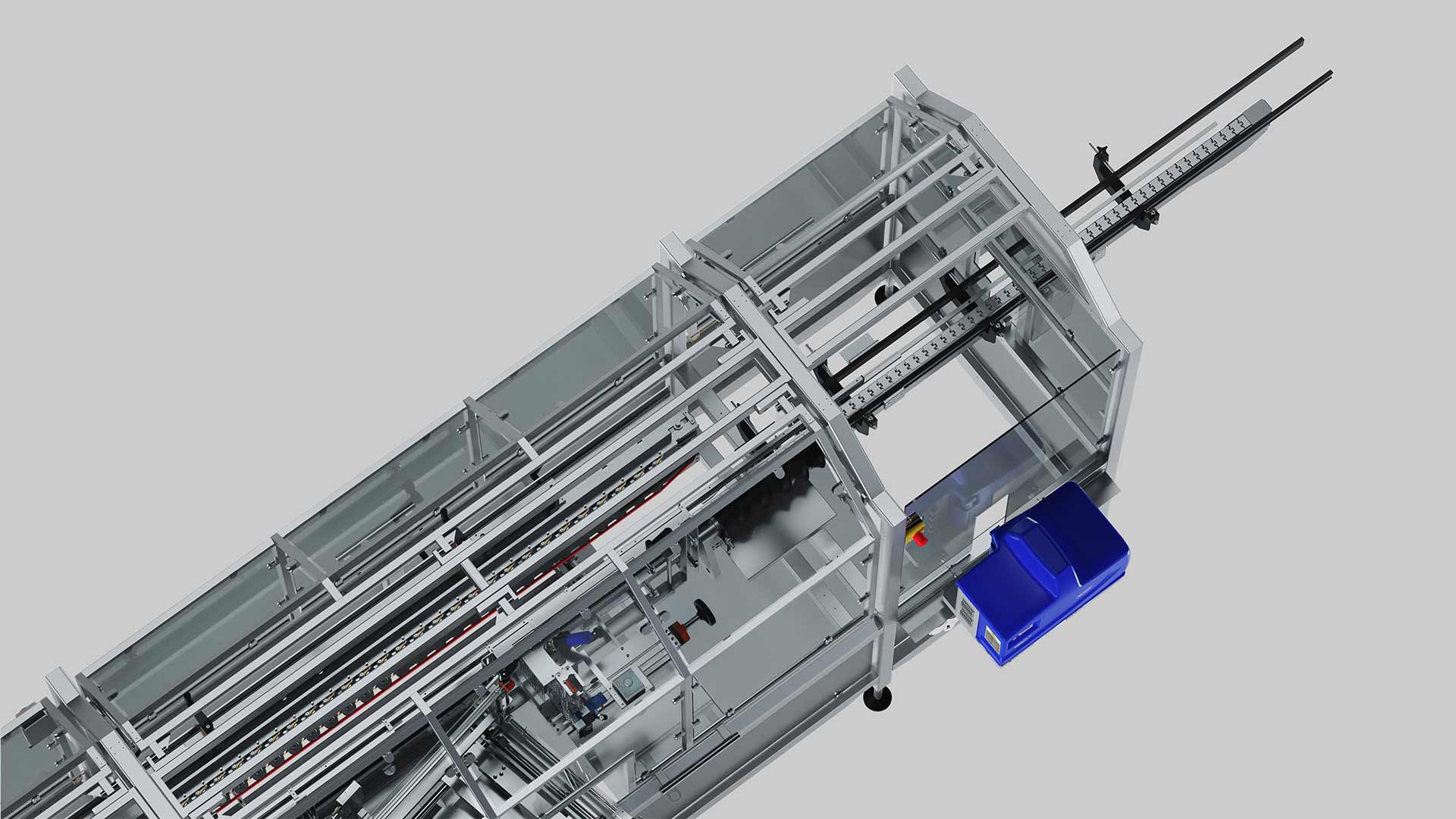

| Base frame: | welded in stainless steel |

| Conveyor: | plastic or steel chain |

| Speed: | Variably adjustable, Gradations referred to reference Ø 73 mm: 300CPM, 400CPM, 500CPM, 750CPM, 1000CPM |

| Infeed: | screw, variable speed |

| Machine length: | infeed and discharge length depending on speed levels Up to 500CPM: 935 mm at infeed, 750 mm at discharge -> total length 6.000 mm 750CPM: 1.185 mm at infeed, 1.000 mm at discharge -> total length 6.500 mm 1000CPM: 1.435 mm at infeed, 1.250 mm at discharge-> total length 7.000 |

| Container Ø: | Min. 66 mm, Max. 165 mm |

| Label height: | In gradations up to 120 mm, 160 mm, 200 mm up to max. 235 mm |

| Label length: | Min. 210 mm – Max. 530 mm |

With its comprehensive functionality, the hotLAN 310 labeller is sure to offer a suitable solution for your industry.

Then do not hesitate to contact us. Together we will look at your request and advise you gladly.