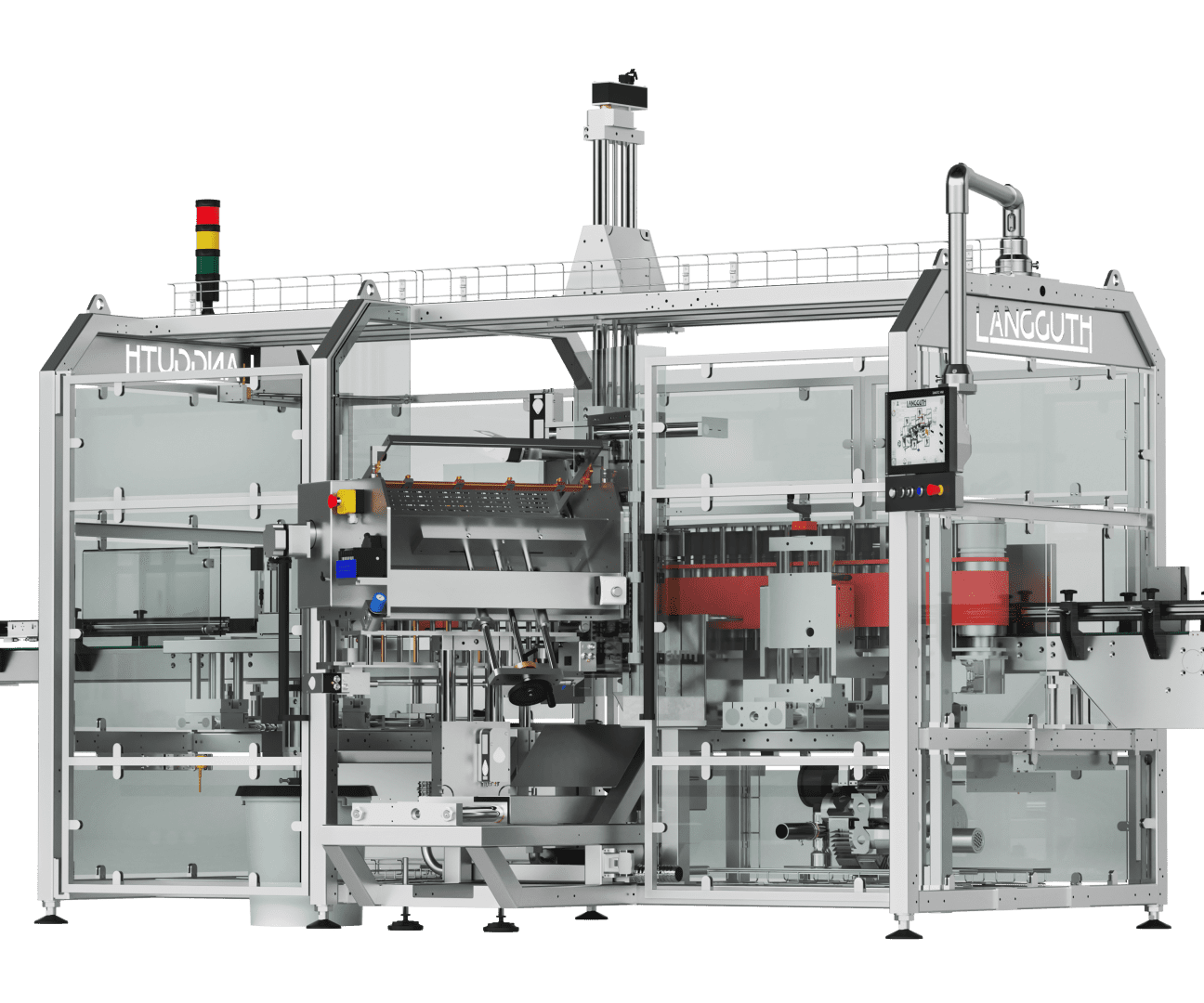

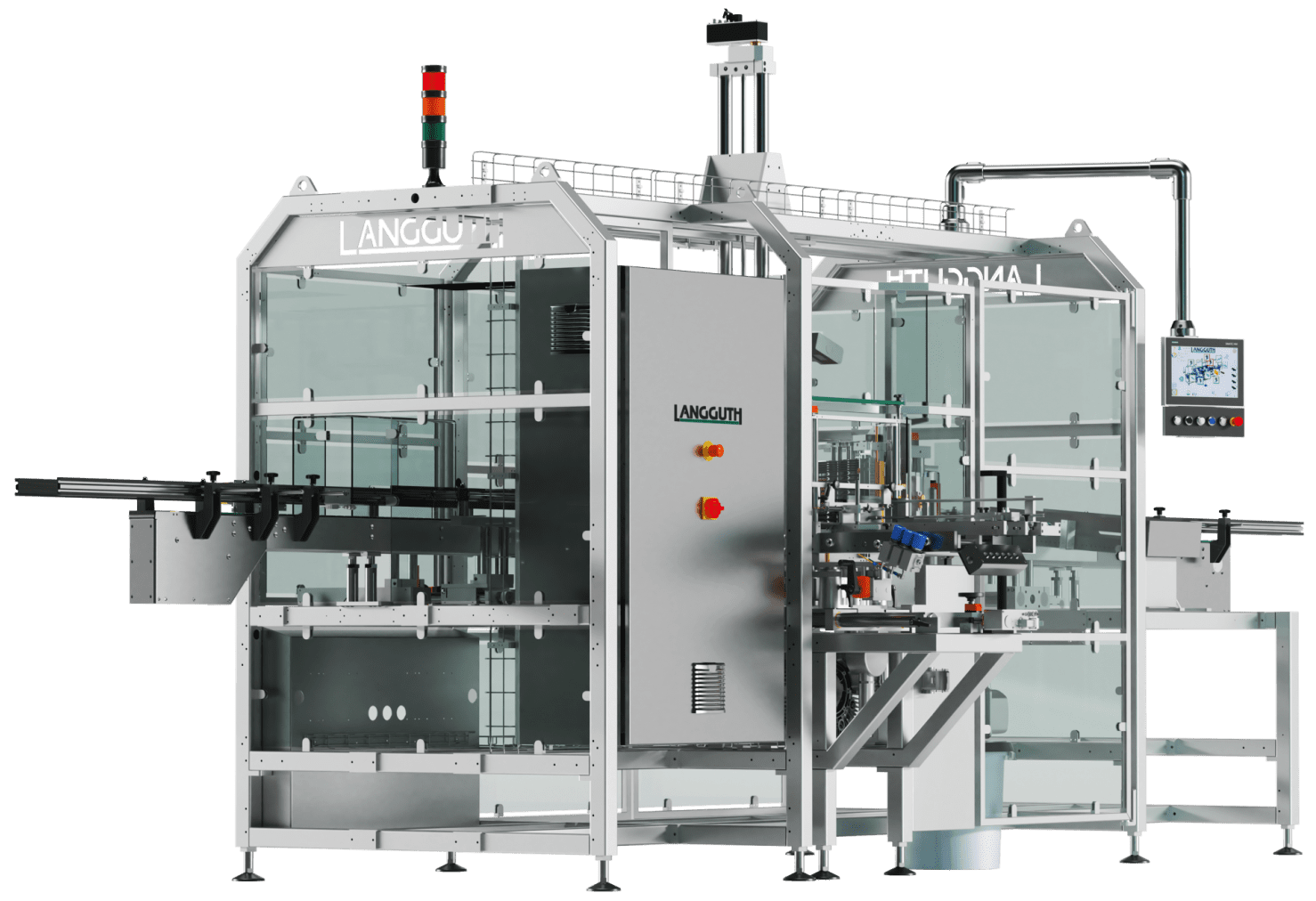

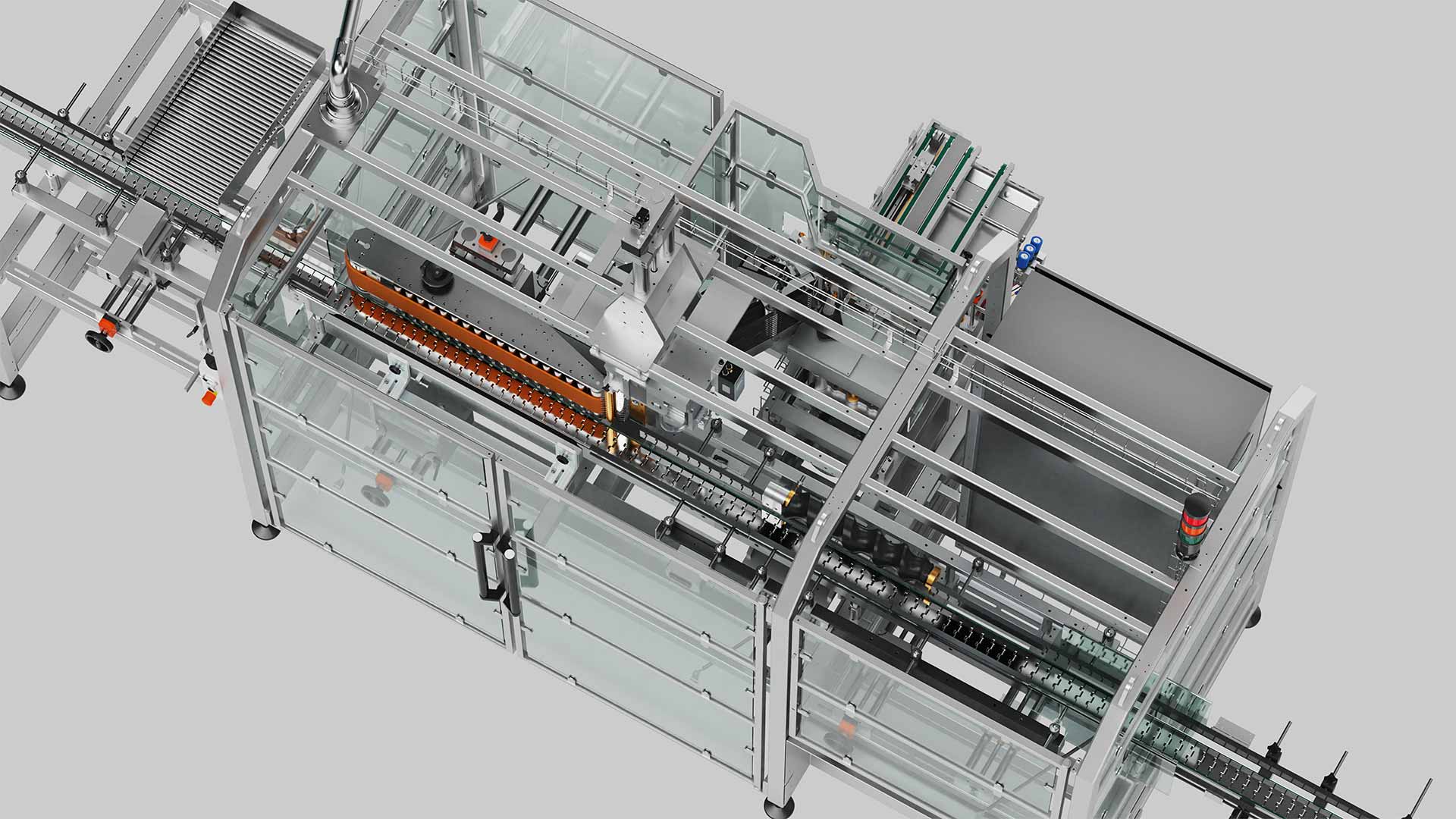

The highest labelling quality for the POS – that’s what GLU|ECO® stands for. The new glue pump concept guarantees constant glue quality, which is essential for the labelling results. Thanks to reproducible adjustments, the glue always reaches the label edges and guarantees therefore high labelling quality. By means of the automatic glue cut-off, the labels can be applied almost without stripes. GLU|ECO® also sets new standards for marketing in terms of design. All shapes and sizes of labels are possible and can even be combined with seal labels.

Climate neutrality is becoming increasingly important for producers. The GLU|ECO® series contributes to this. The consumables are limited to cut and stack labels made of paper as well as conventional and environmentally friendly glues. There is no waste or residue – the final product is easily recyclable. In addition, the machine consumes significantly less compressed air, which is often very cost and energy intensive.

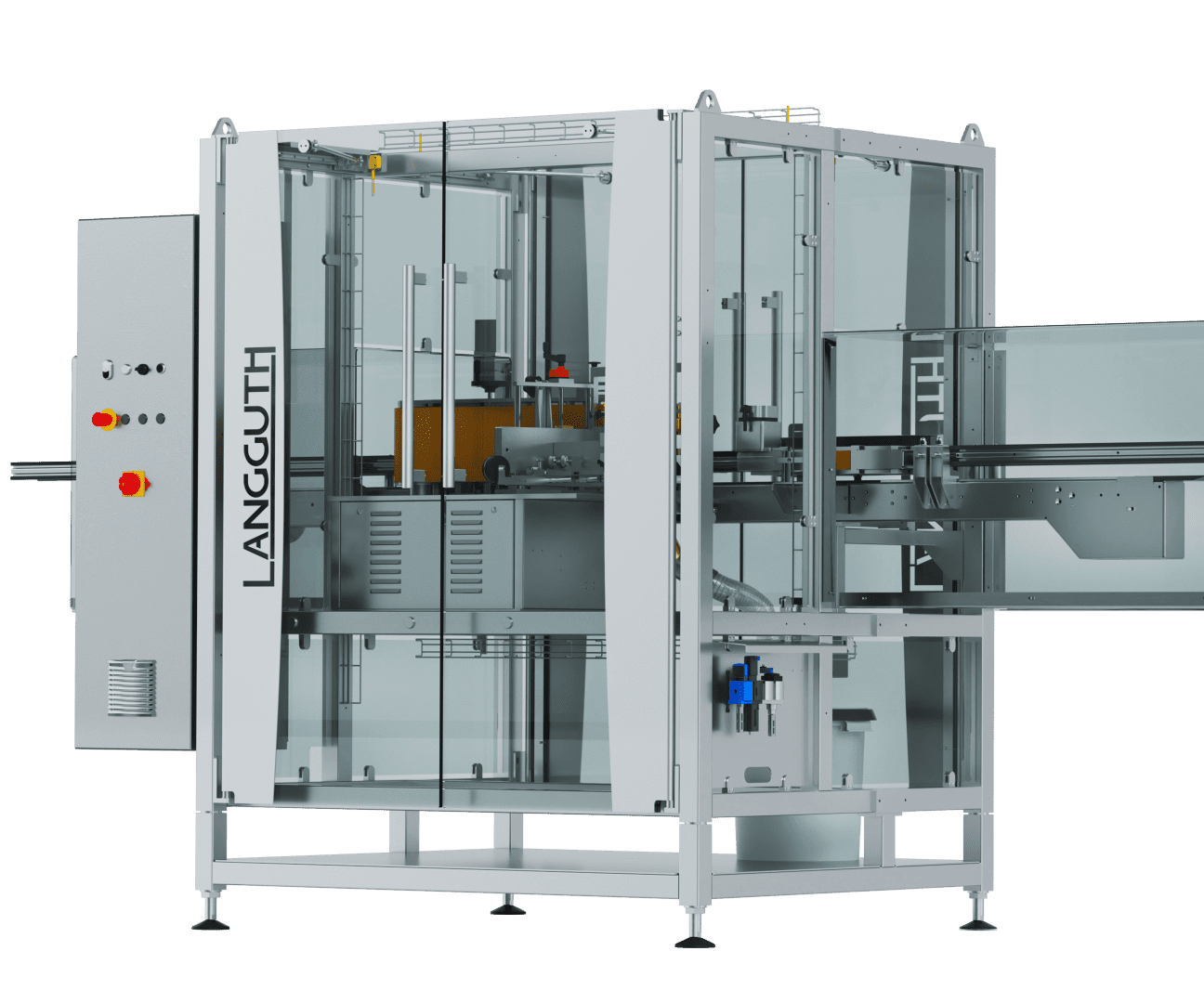

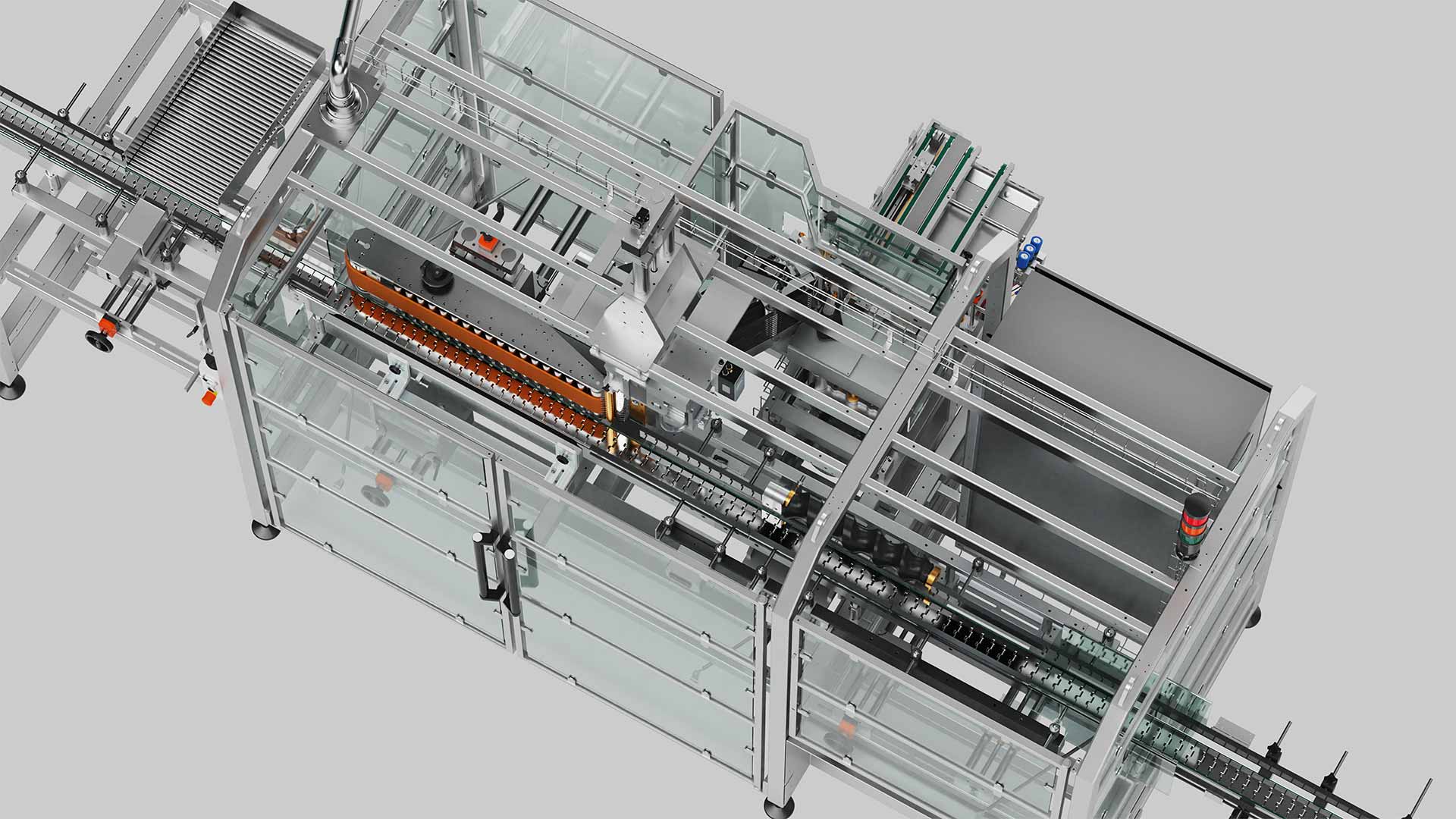

Not only does the few size parts contribute to the very fast set-up processes of the GLU|ECO® machine, but also the automatic height adjustment guarantees a high degree of reproducibility without having to experiment with the perfect setting for a long time. The necessary adjustments are easily accessible and promise a very good labelling quality.

Speed alone is not everything. Although the GLU|ECO® machine covers a performance range of up to 500 CPM, there are very many other advantages that contribute to significant increases in efficiency. With very fast and, in some cases, automatic set-up processes and an overall low-maintenance labeller, the system achieves a high level of availability. Filling the label magazine during production permits a continuous operation. With the CIP (Cleaning in Place) concept, the machine is cleaned on the spot at the touch of a button without requiring additional personnel.

The glue reduction results in a considerable savings potential compared to conventional glueing methods. In addition, the GLU|ECO® machine is low in maintenance and has few size parts. Low TCO and a high ROI lead to a good investment balance. The consumption of materials such as paper labels and glue completes the overall concept for a real cost advantage, without ignoring the high demands on labelling quality.

The revolutionary new glueing system from GLU|ECO® is groundbreaking. Not only does the automatic height adjustment guarantee the best labelling quality, but also due to the innovative design, the parts that come into contact with glue can be cleaned on the spot. The cleaning program is started at the touch of a button, so that no personnel is required. The start-up of the machine is also fully automatic again.

| Base frame: | welded in stainless steel |

| Machine dimensions: | depending on machine version L 4500 x W 1600 x H 1750 mm |

| Label magazine: | fixed with upright label storage, refilling possible during production |

| Container type: | round containers |

| Container-Ø: | Min. 40 mm |

| Label length: | Min. 80 mm, Max. 400 mm |

| Label height: | Min. 40 mm; Max. 315 mm |

| Capacity: | 400 CPM |

| Conveyor elevation: | 820-940 mm |

Thanks to its comprehensive mode of operation, the GLU|ECO labeller certainly provides a suitable solution for your industry.

In addition to main labelling, self-adhesive labellers for cap or seal labels can also be installed in combination. Common industrial printing processes mark labels individually or in batches. For the modern production line and for quality assurance, we use various control systems from sensors to camera systems.

Then do not hesitate to contact us. Together we will look at your request and advise you gladly.