Höchste Etikettierqualität für den POS – dafür steht GLU|ECO®. Das neue Leimpumpenkonzept garantiert eine konstante Leimqualität, die für die Etikettierergebnise essentiell ist. Durch die reproduzierbaren Einstellungen gelangt der Leim immer bis an den Etikettenrand und gewährleistet die hohe Etikettierqualität. Mithilfe der automatischen Leimabschaltung gelingt eine nahezu streifenfreie Applikation der Etiketten. Auch bei der Gestaltung setzt GLU|ECO® neue Maßstäbe für das Marketing. Jegliche Formen und Größen von Etiketten sind möglich und können sogar mit Siegeletiketten kombiniert werden.

Klimaneutralität wird für Produzenten immer wichtiger. Die GLU|ECO® Reihe trägt dazu bei. Die Verbrauchsmaterialien beschränken sich auf Einzelblattetiketten aus Papier sowie aus herkömmlichen und umweltverträglichen Leimen. Es ensteht kein Müll und keine Restbestände – das Endprodukt ist leicht recycelbar. Darüber hinaus verbraucht die Maschine erheblich weniger Druckluft, die häufig sehr kosten- und energieintensiv ist.

Nicht nur die wenigen Formatteile tragen zu sehr schnellen Rüstvorgängen der GLU|ECO® Maschine bei. Auch die automatische Höhenverstellung garantiert ein hohes Maß an Reproduzierbarkeit ohne lange an der perfekten Einstellung zu experimentieren. Die notwendigen Einstellungen sind leicht zugänglich und versprechen eine sehr gute Etikettierqualität, auf die es am Ende ankommt.

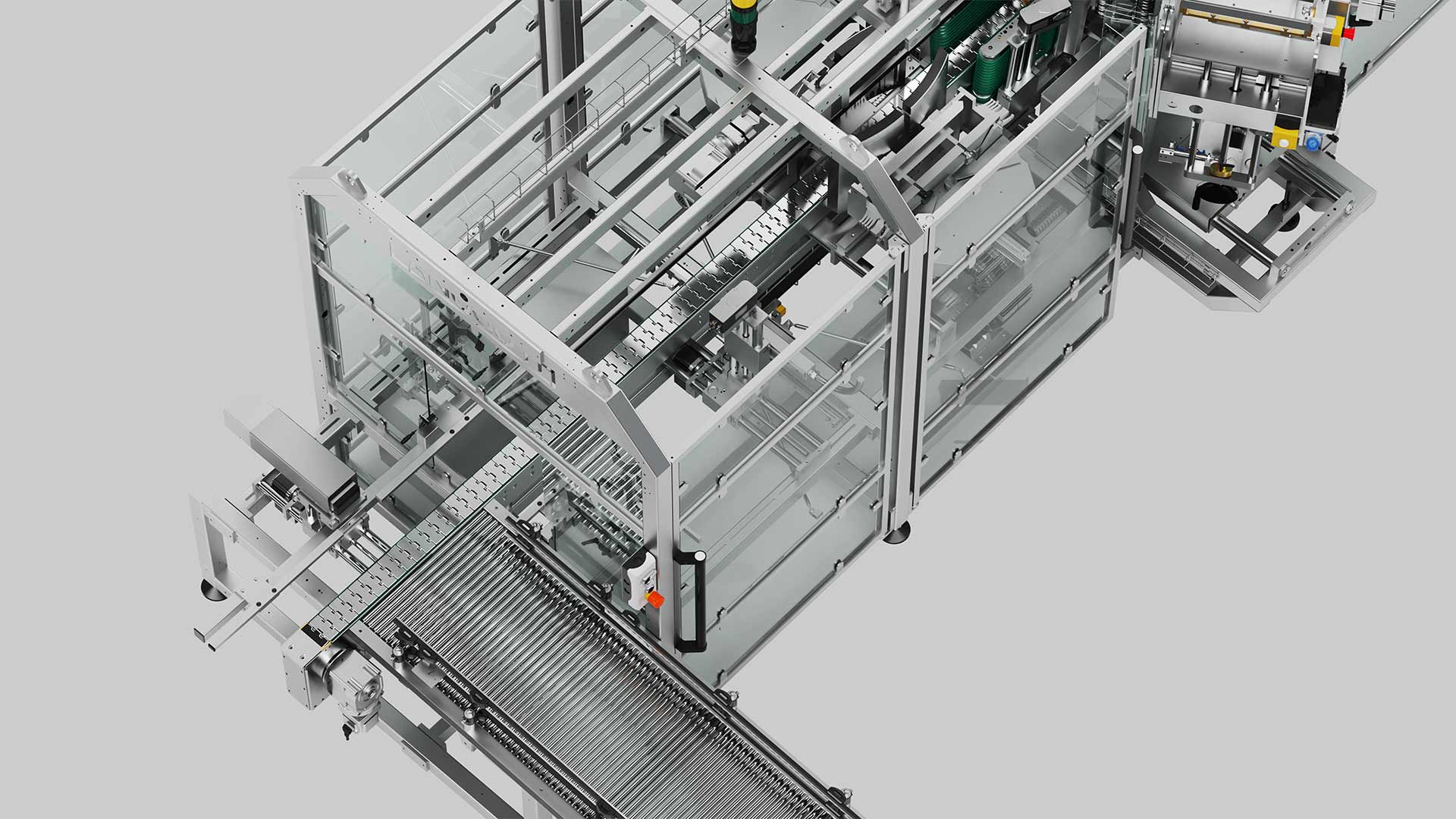

Geschwindigkeit allein ist nicht alles. Obwohl die GLU|ECO® Maschine einen Leistungsbereich von bis zu 500 Takten pro Minute abdeckt, gibt es sehr viele weitere Vorteile, die zu erheblichen Steigerungen der Effizienz beitragen. Mit sehr schnellen und zum Teil automatischen Rüstvorgängen bei einer insgesamt wartungsarmen Etikettiermaschine erreicht die Anlage eine hohe Verfügbarkeit. Die Befüllung des Etikettenmagazins während der Produktion erlaubt einen kontinuierlichen Lauf. Mit dem CIP (Cleaning in Place) Konzept wird die Maschine per Knopfdruck an Ort und Stelle gereinigt, ohne weiteres Personal zu binden.

Durch die Leimreduzierung ergibt sich ein erhebliches Einsparpotential gegenüber konventionellen Beleimungsmethoden. Darüber hinaus ist die Maschine GLU|ECO® Wartungs- und Formatteilarm. Niedrige TCO und ein hoher ROI führen zu einer guten Investitionsbilanz. Der Verbrauch von Materialien wie Papieretiketten und Leim rundet das Gesamtkonzept für einen echten Kostenvorteil ab, ohne dabei die hohen Ansprüche an die Etikettierqualität zu vernachlässigen.

Bahnbrechend ist die revolutionäre neue Beleimung von GLU|ECO®. Nicht nur die automatische Höhenverstellung garantiert beste Etikettierqualität. Mit der innovativen Konstruktion gelingt die Reinigung leimberührender Teile an Ort und Stelle. Per Knopfdruck wird das Reinigungsprogramm gestartet, so dass kein Personal gebunden wird. Auch der Start der Anlage läuft wieder vollautomatisch.

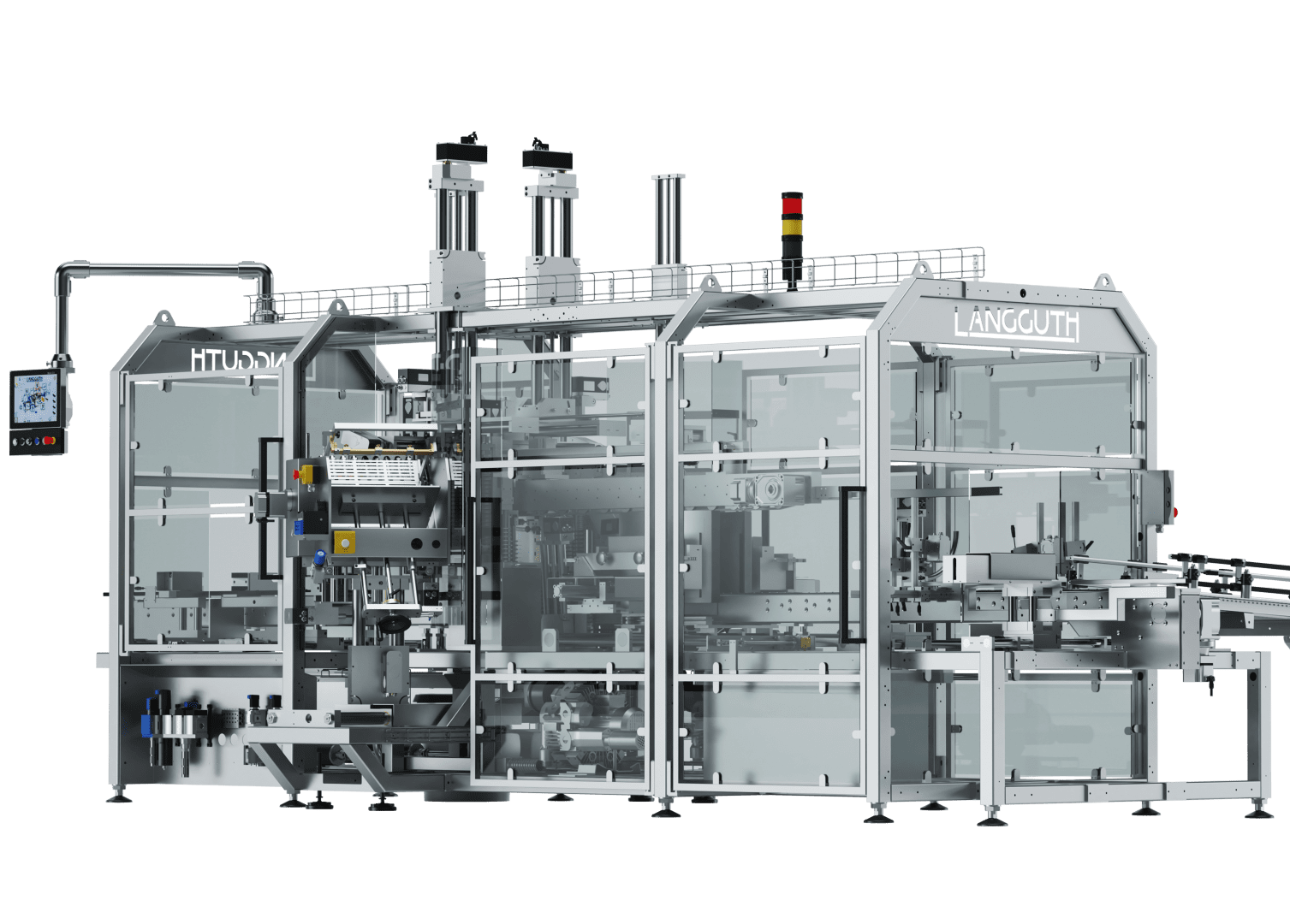

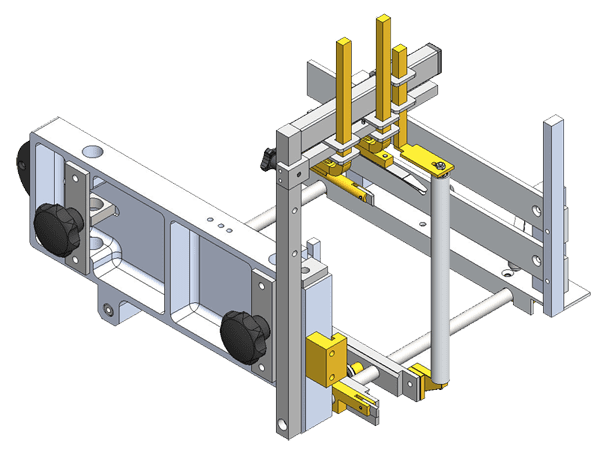

Im FVT 20 – Magazin liegt der Etikettenstapel auf der Nachschiebeeinrichtung zur Entnahme bereit. Die liegende Position der Etiketten erlaubt eine bedienerfreundliche Anwendung gerade für sehr große Etiketten. Durch Auslösen des Etikettenvoreinwurfs entnimmt die bewegliche Saugleiste mit den Vakuumsaugköpfen das jeweils obere Etikett vom Etikettenstapel und übergibt es in den Etikettenschacht zwischen die Einzugsrollen. Hier wird das Etikett bis zur Warteposition transportiert. In diesem Bereich ist eine zusätzliche, positionierte Kennzeichnung auf dem Etikett (beispielsweise MHD-Datum durch einen Ink-JET Schreibkopf) oder eine Code-Kontrolle des Etiketts möglich. Anschließend wird das Etikett an die Leimwalze geführt und beleimt.

| Grundgestell: | Geschweißt aus Edelstahl |

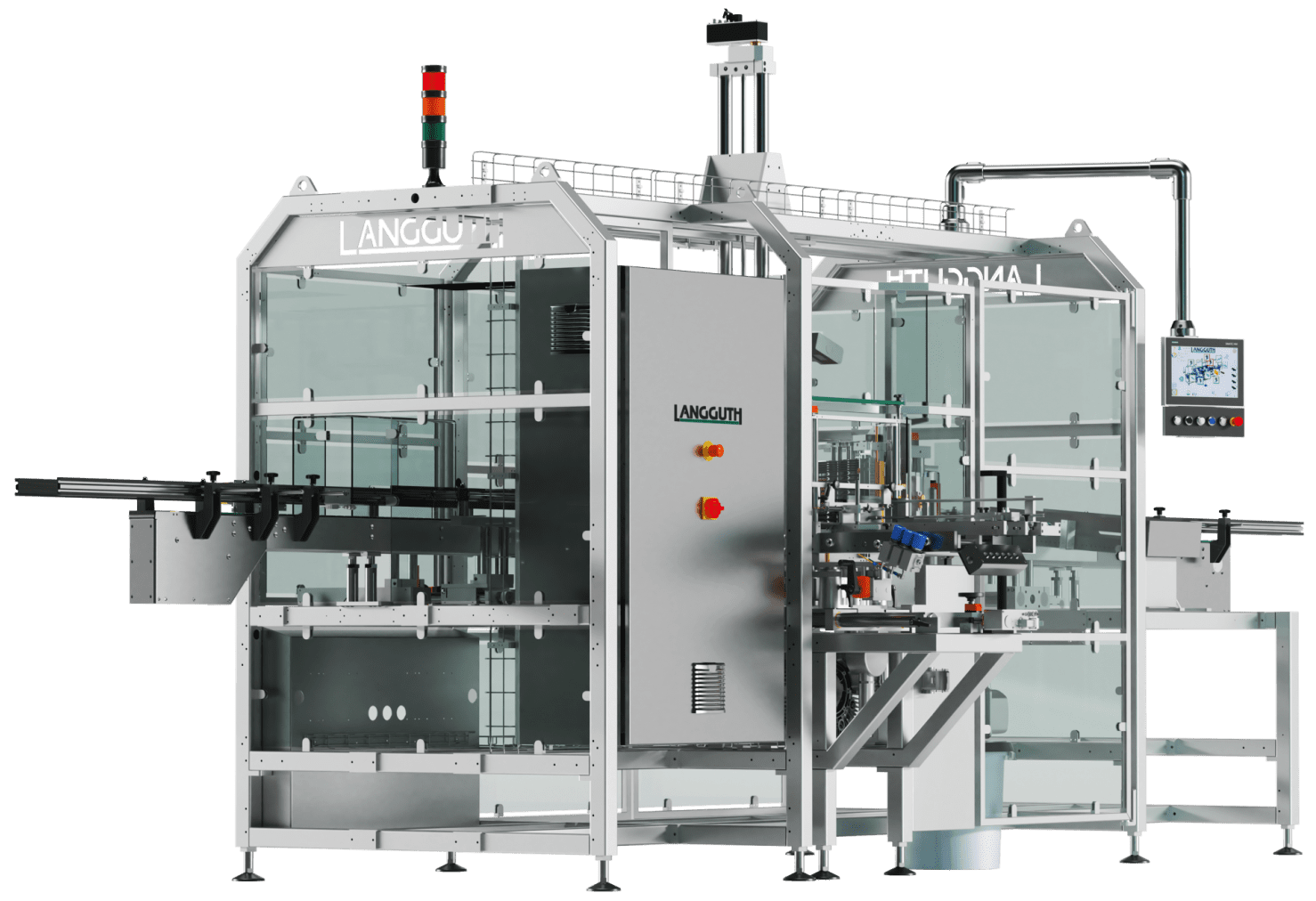

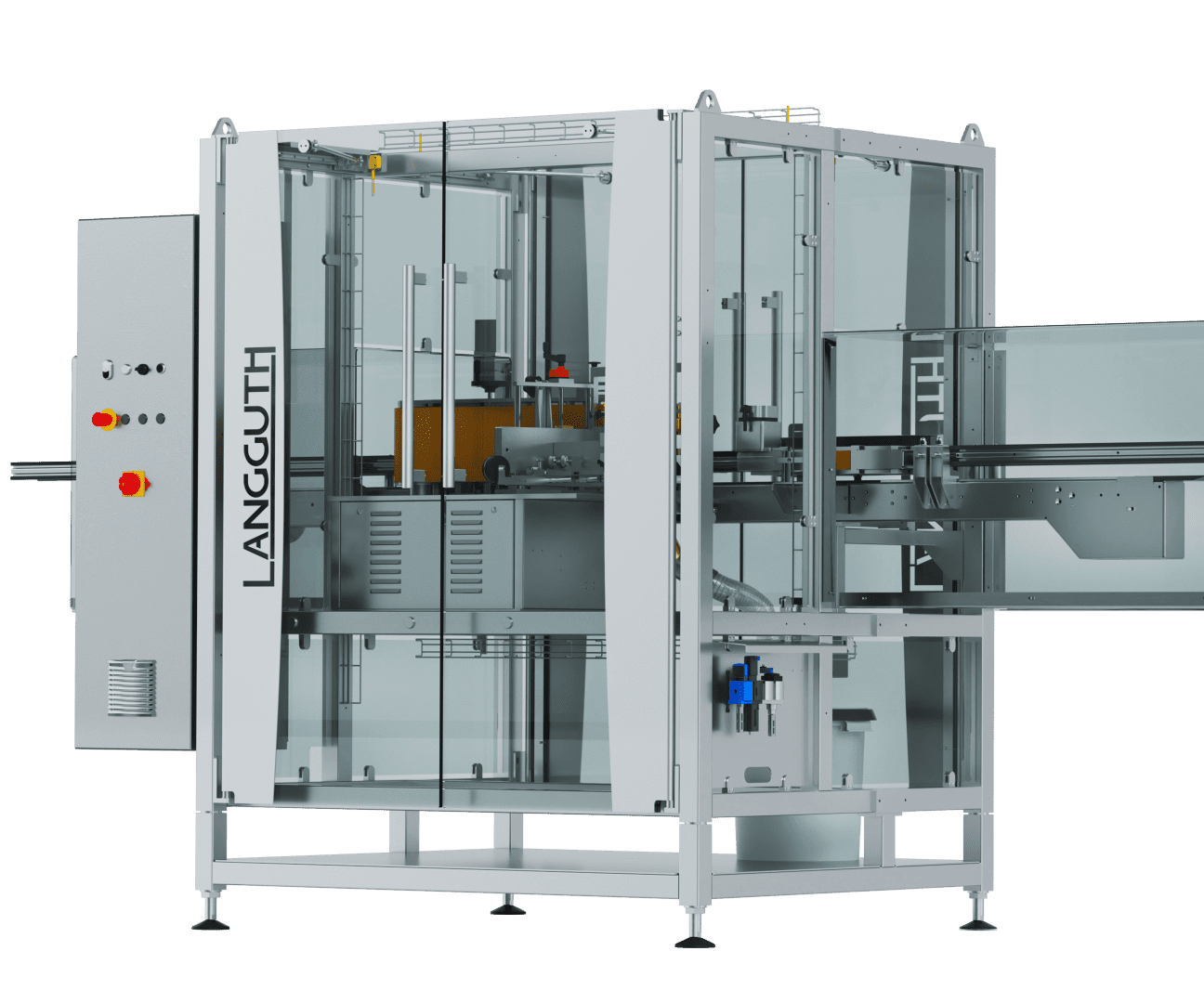

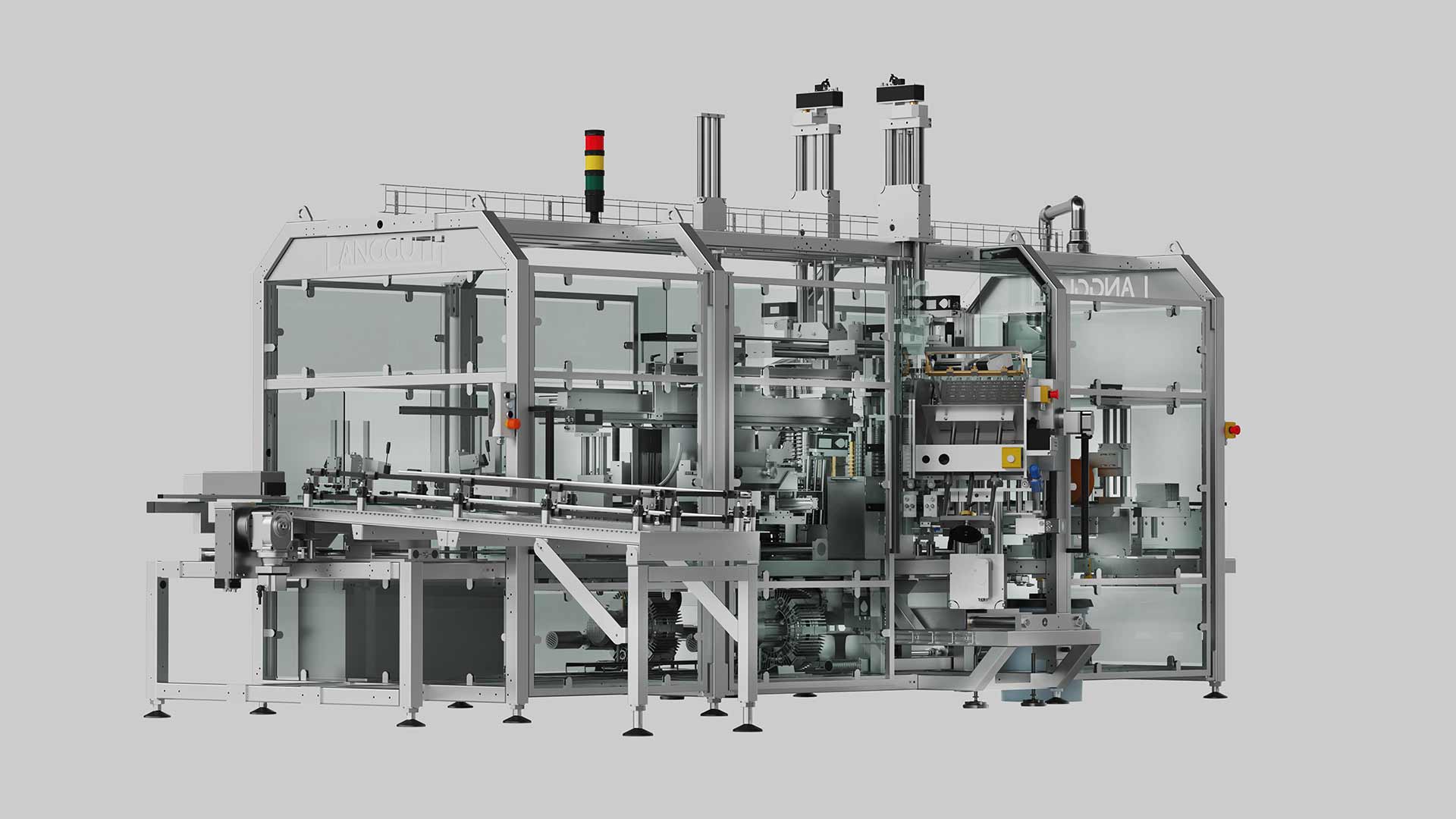

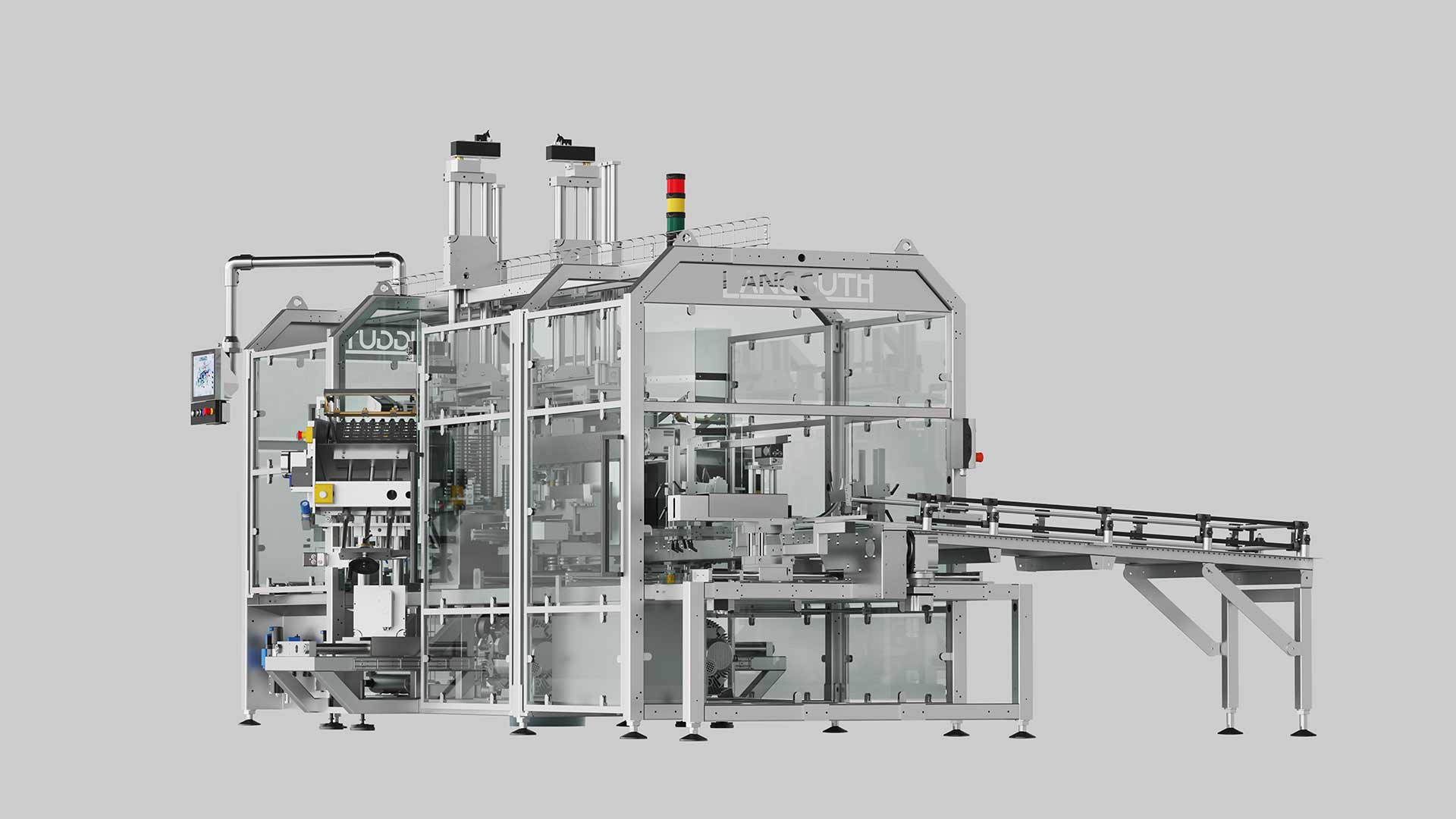

| Maschinenabmessungen: | Je nach Maschinenausführung L 4500 x B 2500 x 1900 mm |

| Gebindeform: | Rund, oval, eckig, konisch |

| Etikettenlänge: | 80 – 650 mm |

| Etikettenhöhe: | 50 – 315 mm |

| Leistung: | 1500 Etikettierungen / Std. |

| Transportband Höhe: | 760-860 mm |

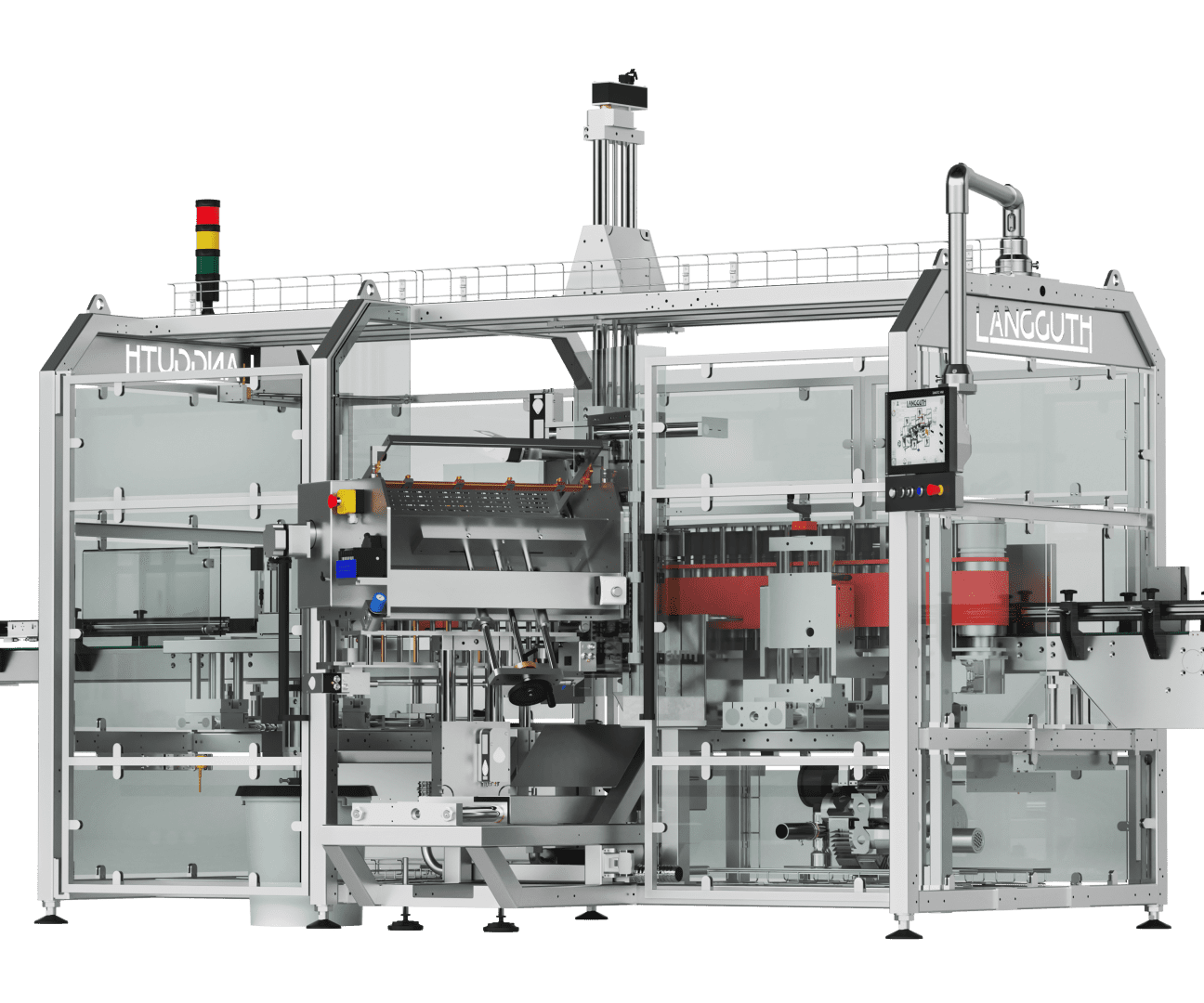

Im Schwingmagazin werden die Etikettenstapel stehend eingelegt. Mit der Etikettenauslösung schwenkt das Magazin vor, so dass die Etikettenvorderkante den Leimfilm an der rotierenden Leimwalze berührt. Mit der Klebekraft wird das Etikett vereinzelt und aus dem Magazin gezogen. In diesem Bereich ist eine zusätzliche, positionierte Kennzeichnung auf dem Etikett (beispielsweise MHD-Datum durch einen Ink-JET Schreibkopf) oder eine Code-Kontrolle des Etiketts möglich.

| Grundgestell: | Geschweißt aus Edelstahl |

| Maschinenabmessungen: | Je nach Maschinenausführung L 4500x B 2500 x 1900 mm |

| Gebindeart: | Rund, oval, konisch, eckig |

| Etikettenlänge: | 80- 395 mm |

| Etikettenhöhe: | 50-315 mm |

| Leistung: | 1500 Etikettierungen / Std. |

| Transportband Höhe: | 760-860 mm |

Durch ihre umfassende Funktionsweise bietet die wetLAN 130 Etikettiermaschine gewiss auch eine geeignete Lösung für Ihre Branche.

Dann zögern Sie nicht, uns zu kontaktieren. Gemeinsam schauen wir uns Ihr Anliegen an und beraten Sie gerne.